Sustainable Solutions for Toilet Paper Manufacturing

Toilet paper manufacturing has significant environmental impacts, from deforestation to the consumption of water generation. As governments and consumers demand more sustainable products, toilet paper manufacturers are focusing on sustainable options to reduce their carbon footprint. This article examines the effective strategies and innovative ideas that are transforming the process of toilet paper production towards sustainability.

Key Environmental Challenges in Toilet Paper Manufacturing

High Water Consumption and Pollution

The production of toilet paper is a water-intensive procedure. Huge amounts of water are used for bleaching, pulping and paper making that can deplete water resources in the local area. Furthermore, the discharge of wastewater containing organic matter and chemicals poses threats to ecosystems of the water in the event that it is not properly handled.

Energy Use and Greenhouse Gas Emissions

The production process requires a significant amount of energy, which is often generated by burning fossil fuels. This leads to substantial greenhouse gas emissions that contribute towards climate changes. Making improvements to energy efficiency and moving towards renewable energy sources is essential to reduce the industrial’s carbon footprint.

Chemical Impact from Bleaching and Processing

Traditional bleaching techniques based on chlorine produce dangerous pollutants like dioxins as well as furans. These harmful substances pose a threat to the health of wildlife as well as human. While chlorine-free bleaching technology has developed, controlling the use of chemicals and ensuring safe processing are still a concern.

Waste Generation and Packaging Issues

Manufacturing produces various waste streams, like sludge and pulp which could clog landfills if they’re not reused or recycled. Additionally, the plastic packaging that is used to make toilet paper causes environmental pollution, posing problems for waste management and recycling infrastructure.

Key Strategies for Sustainable Toilet Paper Manufacturing

1. Sourcing Eco-Friendly Raw Materials

A significant and effective ways to sustain manufacturing toilet paper is making use of environmentally friendly raw materials. Toilet paper traditionally is made from virgin wood pulp which causes deforestation and biodiversity loss.

| Raw Material Type | Description | Environmental Benefits | Considerations |

| Recycled Paper Pulp | Produced from post-consumer and postindustrial recycled paper | Reduces the demand for virgin pulp, reduces the amount of landfill waste | Might require de-inking, and cautious processing |

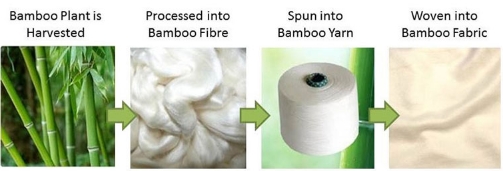

| Bamboo Pulp | Bamboo is a fast-growing plant | Rapidly renewable, with low water and pesticide usage | Processing technology can differ supply chain development |

| Certified Sustainable Wood | Wood is sourced from forests that are that have been certified through FSC, PEFC, or similar organizations | Responsible forest management is ensured and protection of biodiversity | Costs for audit and certification compliance |

| Agricultural Residues | The fibers are extracted from non-wood plants like bagsasse, wheat straw or hemp | Reuses materials from waste, lessens the pressure on forests | Processing challenges, variable fiber quality |

2. Water and Energy Efficiency in Production

Toilet paper manufacturing is energy- and water-intensive. The reduction of energy and water consumption in these industries is essential to sustain the environment. Numerous manufacturers have adopted closed-loop water systems which recycle and treat the water inside the facility, drastically cutting down on freshwater consumption. In terms of energy the investment in energy-efficient machinery and the incorporation using renewable power sources like solar wind, biomass, or even wind have helped reduce carbon footprints. These efficiency gains do not only improve the environment, but they also lower operating costs.

3. Eco-Friendly Chemical Processes

Bleaching is essential to create the white, clean appearance people want, but conventional bleaching using chlorine emits harmful toxins into the environment. To combat this, a lot of producers have shifted to chlorine-free (ECF) or completely free of chlorine (TCF) bleaching techniques that drastically decrease the harmful by-products. The reduction of the use of fragrances, dyes and other chemical additives can further improve the biodegradability and safety of the end product.

4. Sustainable Packaging Solutions

Packaging is a significant contributor to how much impact toilet paper has on the environment. The shift away from plastic films towards compostable, recyclable or biodegradable packaging can reduce the amount of plastic waste and landfill waste.

| Packaging Solution | Environmental Benefits | Considerations |

| Recyclable Paper-Based Packaging | Reduces plastic waste, and supports recycling programs | You must ensure that you have moisture resistance and longevity |

| Biodegradable and Compostable Wraps | Reduces the amount of waste in landfills and plastic pollution | Requires proper composting facilities |

| Plastic-Free Packaging | Minimizes the carbon footprint of microplastics and reduces their pollution | Might require new coatings to protect the product |

| Minimalist Packaging Design | Reduces waste and resource consumption | Protecting yourself with less materials |

| Use of Recycled Content | Reduces consumption of resources and decreases the need for materials that are not virgin. | Quality and printability have to be kept up |

| Water-Resistant Eco Coatings | Allows the alternative paper options in place of plastic | The coating should not contain any toxic chemicals and be recyclable. |

5. Waste Reduction and Circular Economy Practices

It is vital to reduce waste for sustainable manufacturing. Manufacturers can reuse pulp scraps and production trimmings to be used in the production process which reduces the consumption of raw materials. The by-products can then be used for biomass fuel or composted, thereby closing the loop of resources and reducing waste in landfills. The circular economy approach allows companies to increase efficiency in resource use throughout the entire lifecycle of their products.

6. Certification and Transparency

Third-party certifications such as FSC, PEFC, or Green Seal can provide confirmation that products comply with stringent environmental standards.

| Certification/Transparency Aspect | Description | Benefits | Examples |

| Forest Certification | Verifies sustainable forest management practices | Increases trust among consumers and supports environmentally friendly marketing | FSC (Forest Stewardship Council), PEFC (Programme for the Endorsement of Forest Certification) |

| Environmental Product Declarations (EPDs) | Documents that are standard for reporting the environmental impacts of products | Gives transparent information on the lifecycle impact of similar lives | ISO 14025-compliant EPDs |

| Eco-label Certifications | Products that are marked as meeting certain environmental standards. | Increases trust among stakeholders and increases accountability | EU Ecolabel, Green Seal, Nordic Swan |

| Carbon Neutral Certification | It is confirmed that carbon emissions have been quantified and offset | Shows the commitment to mitigate climate change | PAS 2060, Carbon Trust Standard |

| Sustainability Reporting | Public public disclosure of environmental performance and the goals | Public disclosure of environmental performance and the goals | Corporate Sustainability Reports, GRI Standards |

| Third-party Audits | Independent Verification of environmental claims and procedures | Validates credibility and conformity | SGS, Bureau Veritas, Intertek |

7. Consumer Awareness and Engagement

The need to educate consumers on the impact on the environment of their purchases is a crucial component of sustainable manufacturing. Marketing campaigns and clear labeling will highlight the advantages of toilet paper that is eco-friendly in order to encourage responsible consumption. Involving consumers in the process creates an appetite for environmentally sustainable goods, and helps in long-term change in the industry.

Future Trends in Sustainable Toilet Paper Manufacturing

As the awareness of environmental issues increases and the toilet paper industry is rapidly evolving to adopt more sustainable manufacturing methods. The Demand for environmentally-friendly products, in conjunction with advancements in technology and the sourcing of raw materials, are shaping the future of toilet paper manufacturing.

1. Adoption of Alternative Raw Materials

One of the biggest advancements in the coming years is the growing utilization of alternative fibers that go beyond the traditional wood pulp. Fast-growing plants such as bamboo, hemp, and agricultural residues like wheat straw are gaining attention. These renewable resources need less water, fewer pesticides and have shorter growth cycles and are therefore environmentally beneficial. The ongoing research focuses on the process of converting these fibers to toilet paper, such as bamboo toilet paper, recycled paper, etc, that is soft and durable that can meet the needs of consumers.

2. Integration of Smart Manufacturing Technologies

Digital transformation plays an important role in improving sustainability. The combination AI (AI), Internet of Things (IoT) and sophisticated sensors allows companies to measure their use of resources, like energy and water–in real-time. These intelligent systems improve efficiency of production, cut down on the amount of waste and reduce carbon emissions. Once this technology becomes widely available and widespread in the field.

3. Shift Towards Renewable Energy Sources

To lower the greenhouse gas emissions from manufacturers of toilet paper are switching to renewable sources of energy like wind, solar and biomass. A lot of companies are installing renewable power installations on their premises or buying credit for green energy. This change is vital to reaching global climate targets and attracting environmentally conscious buyers.

4. Eco-Friendly Bleaching and Chemical Processes

The conventional bleaching processes based on chlorine are being replaced with environmentally more sustainable alternatives. Enzymatic and oxygen-based bleaching helps to reduce the release of toxic byproducts into the waterways. Future developments are anticipated to create even greener chemical processes that ensure high-quality products and minimize environmental impact.

5. Sustainable Packaging Innovations

Packaging waste is an increasing issue for regulators and consumers alike. The future of environmentally friendly toilet paper packaging is based on biodegradable film and paper wraps that are recyclable, and minimalist designs that cut down on the amount of material used. Businesses are also looking into options for compostable packaging to ensure that packaging materials don’t cause litter or cause pollution to the environment.

Summary

Sustainable solutions in toilet paper manufacturing are not only vital for environmental preservation and they also present a strategic opportunity for innovation, efficiency and brand differentiation. Through the use of eco-friendly materials, reducing resource consumption, minimizing waste and engaging consumers, manufacturers can meet the environmental challenges while ensuring their role towards a more sustainable future.