Key Quality Standards for Bamboo Tissue Paper

Bamboo tissue paper is quickly becoming a favourite substitute for traditional wood-pulp tissue paper products. The popularity is a result of the need for sustainable products and new advancements in manufacturing technologies. On the other hand, meeting quality standards and ensuring product consistency and safety is critical. The following analysis discusses the quality criteria and international standards that grade quality bamboo tissue paper.

Why Quality Standards are Important in a Growing Market

Global bamboo tissue paper production is lucrative and at the same time, the standards concerning it are lax. Without the proper guidelines, businesses can use non-existent regulations to support claims like ‘eco-friendly’ and ‘all-natural’ and conceal the use of low-quality, potentially harmful products. Quality regulations are critical in guiding producers in the eco-friendly bamboo industry and fulfilling the buyers’ expectations.

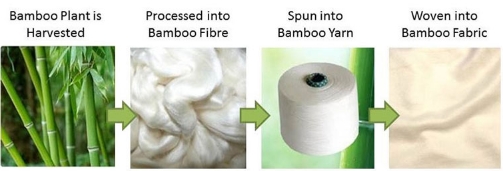

Raw Material Standards for Bamboo Tissue Paper Production

More and more consumers value the quality, safety, and the sustainability of bamboo tissue paper products. Hence, it is expected that manufacturers implement and abide by the defined, sustainable, and ethical standards in the bamboo industry concerning the harvesting, processing, and the assessment of bamboo prior to refining it into soft sheets.

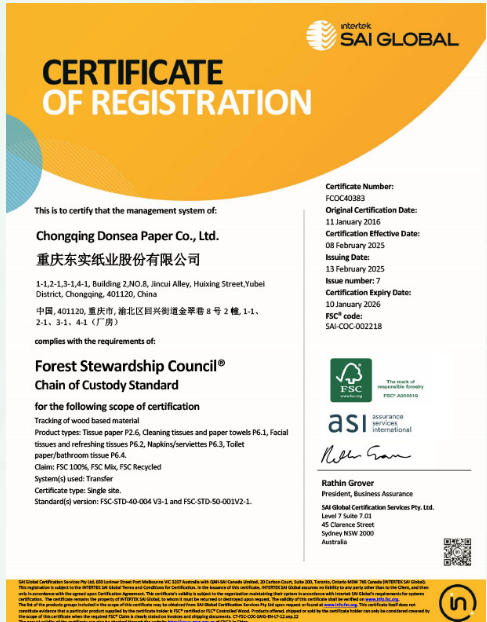

1. Ensuring Sustainable Bamboo Sourcing

As with any tissue production, the first and foremost consideration with bamboo production is the sustainability of the bamboo source. Responsible sourcing entails that bamboo is harvested from plantations that are managed rather than from natural forests, which protects habitats and the environments from degradation. Bamboo harvested from eco-positive plantations is applied for various certificates such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC). These certifications also promote the protection of biodiversity, responsible land use, and fair treatment of workers in the bamboo supply chain.

Furthermore, it is the responsibility of the purchaser to ensure the bamboo is harvested at the proper stage of maturity, which is preferably between three and five years. Only mature bamboo tissue will yield better, longer fibres which will improve the durability and softness of the tissue. Immature bamboo will result in weaker pulp and more variability in the texture of the tissue.

2. Fibre Purity and Quality

The performance of the final product is determined by the quality of the tissue fibres and the bamboo tissues. Quality bamboo pulp should comprise unhindered cellulose bamboo fibres and little to no other fibres, plant materials, or conflicting recycled pulp. If the pulp is disqualified and mixed fibres are present, the softness of the tissue is variable, strength is lost, and biodegradability is hindered.

To avoid compromising the purity of fibre, leading producers utilise state-of-the-art mechanical and chemical pulping techniques to extract cellulose while preserving the integrity of the natural fibre structure. Evaluating uniformity and consistency across production lots involves the analyses of fibre length distribution and the quantification of lignin and other related attributes.

3. Eco-Friendly Ways of Pulping and Bleaching

Pollution and chemical waste minimalisation is a requirement of socially responsible bamboo pulp production. Conventional pulp production and processing methods, especially bleaching, involve the use of chlorine, which leads to hazardous by-products like dioxins. Therefore, bamboo tissue makers must use Elemental Chlorine Free (ECF) and Totally Chlorine Free (TCF) methods to eliminate such risks.

Modern bleaching techniques involving the use of oxygen, hydrogen peroxide, and ozone in lieu of chlorine, achieve the same brightness and cleanliness of pulp while decreasing the environmental consequences. Top compliance with ISO 14001 environmental management systems and the EU Ecolabel proves that all the pulping stages meet the standards of international environmental protection.

4. Chemical Safety and Additive Regulations

Standards for raw materials imply the need for chemical safety during the preparation of bamboo pulp. During the preparation of the pulp, any additives, such as softeners and strength enhancers, must be non-toxic, biodegradable, and permitted for use in personal-hygiene paper tissues. In Europe, manufacturers must adhere to the toxic chemical policies called REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), and in the USA, the FDA (Food and Drugs Administration) guidelines to guarantee safe and non-toxic product residues.

To be safe for skin contact and not cause irritation or allergic reactions, tissue paper must be tested for heavy metals, formaldehyde, and other possible contaminants. Dermatological approval is sought by many manufacturers to confirm the hypoallergenic status of their bamboo tissue products.

5. Fibre Performance Evaluation

Bamboo fibers must undergo a range of physical and mechanical assessments before they are qualified to be used in the production of tissues. The length, tensile strength, absorbency potential, and softness index are the key parameters that are tested. Tissue paper that is softer and stronger is produced from longer and smoother fibres, while the higher the cellulose content, the greater the absorbency.

To ensure each batch of bamboo material fulfils industry performance expectations, pulp quality is tested according to ISO 12625 guidelines. Adhering to these standards helps maintain the softness, durability, and comfort of the finished tissue product for the end consumer.

6. Promoting Traceability and Transparency

Raw material standards require bamboo tissue paper manufacturers to take traceability and documentation to a certain level. Since bamboo documentation is timestamped, it is easy to trace each batch from harvest to production. The traceability system makes it possible to attribute every batch of tissue to a particular batch of bamboo.

The traceability system login provides enough data to issue international traceability and sustainability certificates. This provides end consumers with tissue that is ethically produced, thus, meeting responsible tissue production guidelines. Transparency promotes trust and accountability.

Standards for Physical and Mechanical Properties in Bamboo Tissue Paper

During use, the physical and mechanical properties of bamboo tissue paper determine how it feels, performs, and endures. As opposed to typical paper, however, bamboo tissue must maintain a careful equilibrium between softness and strength. Consistent and predictable properties are the result of standardized testing, which allows manufacturers to provide high-quality and reliable tissue products that are soft and strong, to customers and regulators alike. The most recognized international standards for testing and evaluating performance of tissue papers are the ISO 12625 standards which specify testing methods and performance parameters, including thickness, tensile strength, softness, absorbency, and steam drying.

1. Basis Weight and Thickness

Thickness and basis weight are the most basic quality parameters of tissue paper. The paper’s basis weight, which is the weight of the paper for a given area, is generally accepted as a criterion of quality and stated in g/m². It guides the density and general feel of the tissue. Thickness, however, influences softness, pliability, and the sense of luxury.

The weight of bamboo tissue paper ranges from 12-20g/m² for lightweight facial tissues increasing to 25-35g/m² for more absorbent paper towels. Standardized methods for measuring such parameters is outlined in ISO 12625-3 to ensure consistency in the end products. Predictable performance is ensured when the basis weight and thickness of a tissue roll or sheet is uniform along its length. It eliminates the risk of tearing as well as an uneven texture while in use.

2. Tensile Strength and Durability

Tensile strength refers to the resistance of a material to tearing and is of great importance in the bamboo tissue sector as customers anticipate a product to be both soft and strong (especially in the wet state). ISO 12625-4 and ISO 12625-5 assess dry and wet tensile strength, respectively, while 12625-3 provides insight on bamboo fibre cohesiveness on tensile and stress.

It is essential to have an equilibrium of softness and tensile strength in tissue paper. If a tissue is too strong, it will be stiff, and if it is too weak, it will be taut along its surface and tear easily. As the fibres of bamboo are long, the tensile strength will naturally enhance. This is an advantage, as less chemical reinforcement will be needed, greater environmental integrity will be maintained while still providing the necessary performance.

3. Absorbency and Water Retention

The exceptional absorbency of bamboo tissue paper highlights how well the paper captures and holds moisture. Absorbency can be broken down into two measurements: the absorption capacity and the absorption time. Absorption capacity is the weight of water that is absorbed by the paper and the absorption time is how rapidly the tissue absorbs moisture. For this type of analysis, manufacturers follow ISO 12625-8 and the accompanying standards proposed for these absorbency measurements.

All bamboo tissues should be able to rapidly absorb moisture, and the volume of moisture absorbed should be sufficiently large to support rapid absorption and high capacity. Water absorbency enhances softness which is pronounced in the paper. This is the result of upper layers of the paper absorbing water, relaxing, and then feeling softer.

4. Softness and Surface Smoothness

For personal tissues, the softness of the tissue paper is a major factor. The bamboo fibres being used in the tissue paper are also smooth and rounded which adds to the softness of the tissue paper that is in direct contact with the skin. Ensuring even higher tissue softness through the refining and the creping stages is most important. This is to prevent varying levels of softness on different areas of the tissue paper.

Softness can be determined through chemical and sensory testing. There is no global standard for determining softness, and most manufacturers rely on ISO standards and tactile testing methods to ascertain consumer softness thresholds.

5. Stretchability and Elastic Recovery

Stretchability, or elongation at break, is defined as the maximum distance a tissue can elongate before it ruptures. This is an important property for thin and multi-ply tissues to ensure flexibility and avoid ruptures during use. ISO 12625-4 describes test methods on the elongation and elastic recovery of a tissue under tensile pulling to determine the stretchability of a tissue.

Over-refining during pulping reduces the flexibility of bamboo tissue. So to avoid this, manufacturers should optimise processing methods to maintain the balance of flexibility in the fibres along with uniform strength, stretchability and texture.

6. Porosity and Air Permeability

Porosity is a measurement of how easily a material allows the passage of air and liquid. ISO 5636 standards are used for measurement of air permeability for tissue products. For bamboo tissue paper, it is important to keep a balanced weight for porous tissue. The resultant tissue should be breathable as well as absorbent for ideal towel and napkin drying.

7. Compliance with International Testing Standards

To maintain reliable quality, bamboo tissue paper manufacturers engage with globally recognised testing and certification frameworks. For testing physical and mechanical properties covering tensile strength, absorption, and thickness, the various parts of the ISO 12625 series is the standard. Consistency and standards in production and testing processes are achieved through the incorporation of the ISO 9001 quality management systems, which many manufacturers cite. For consistency across markets and psychometric alignment with consumer expectations regarding premium quality hygiene products, bamboo tissue products will always be compliant with the stated standards.

Hygiene and Safety Standards in Bamboo Tissue Paper

Hygiene and safety are fundamental to quality assurance in tissue paper manufacturing. As the bamboo tissue paper products, whether bamboo facial tissue, bamboo toilet paper or bamboo kitchen paper towels, are for everyday intimate use, each production stage, including packaging, must meet defined standards. International standards must be observed to ensure the absence of harmful substances, microorganisms, or residues during production.

1. Microbial Cleanliness and Contamination Control

A primary hygiene concern during the manufacturing process is the microbial cleanliness of the finished tissue paper products. As with all tissue paper products, potential bacterial, fungal, and sporiferous microbial tissue paper product contamination must be avoided. The cleanliness of the paper products is determined and assessed by tests conducted under ISO 8784-1 and ISO 8784-2 which evaluate the total bacterial and fungal contamination of a paper product.

To achieve control over microbial contamination, manufacturers implement preventive measures which include the use of sterilized production environments, purified water, and air filtration systems. Routine sanitation of equipment and storage areas, and employee hygiene training and protocols help minimize contamination risks during production and packaging.

2. Allergen-Free and Skin Compatibility Testing

The tissue paper products finished with bamboo must include a dermatological test that must be certified so that the product is validated to be hypoallergenic and will not cause any irritations. The test defined under the international dermatological standards will determine the compatibility of the tissue with sensitive skin types.

The natural bamboo that serves as a material for hygiene products possesses natural hypoallergenic and antibacterial properties; therefore, safety must be guaranteed that these properties will not be altered after the processing steps. Certifications of no-opaque and no-allergenic irritants for products are assigned following skin patch tests conducted by independent private laboratories. Thus, resulting products are dermatologically tested and hypoallergenic validated.

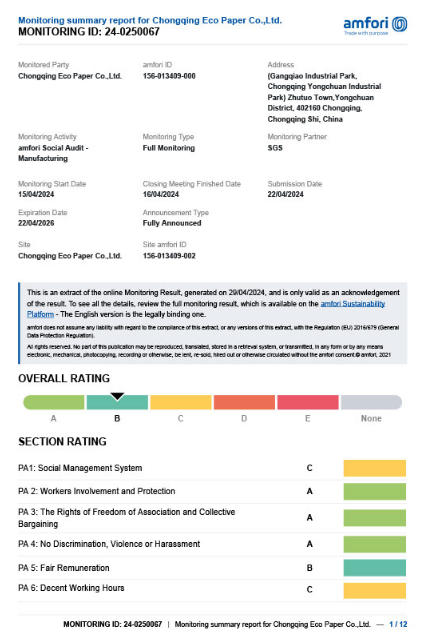

3. Hygiene in Manufacturing and Packaging

To ensure contamination does not occur during production, manufacturing and production facilities must be clean and controlled. Bamboo tissue manufacturers must follow Good Manufacturing Practices (GMP) and ISO 22000 standards. Production area dust control measures, and temperature controlled storage facilities, minimize and stop microbial growth.

Packaging must also ensure hygiene. It must maintain the tissue’s softness and integrity, and protect the tissue from moisture, dust, and other external contaminants. Sustainable goals are met by the use of sealed tamper-proof packaging which is recyclable or biodegradable. Safe storage and expiration dates are clearly labeled, ensuring the product is fresh and safe for the consumer.

4. Compliance with International Certifications

Multiple global standards and certifications are recognized and followed by reputable bamboo tissue paper producers. These certifications are one of the best methods for verifying hygiene and safety practices. Certifications include:

- ISO 8784: Cleanliness of Microbes in Tissue Paper

- ISO 9001: Quality of Management Systems in Safe and Consistent Products, and Safe performance

- ISO 14001: Clean production with Sustainable Environmental Systems

- Dermatological Safety Certifications: Independent testing confirming hypoallergenic and skin-safe properties.

These certifications ensure hygiene, and strengthen health, consumer protection, sustainability, and safety of a product’s brand.

5. Protecting Consumers and the Environment

Bamboo tissue paper manufacturers implement environmentally friendly hygiene and safety standards. Adopting safe chemical processes, using biodegradable additives, and implementing reusable and recyclable packaging materials all minimize production-related pollution. Protection of the environment during production processes demonstrates the manufacturer’s commitment to eco-friendly principles. Adopting and following these standards illustrates the manufacturer’s commitment to the circular economy and the coexistence of hygiene and environmentally responsible production.

Environmental Certifications for Quality in Bamboo Tissue Paper

| Certification | Organization | Purpose | Key Requirements | Benefits |

| FSC Certification | Forest Stewardship Council | Ensures bamboo is sourced from responsibly managed forests and plantations. | Traceable supply chain, responsible land use, biodiversity protection, and fair labor practices. | Demonstrates ethical sourcing and enhances consumer trust in sustainability claims. |

| PEFC Certification | Programme for the Endorsement of Forest Certification | Promotes sustainable forest management through third-party certification. | Verifiable origin of raw materials, compliance with environmental and social standards. | Expands market access to eco-conscious consumers and retailers. |

| EU Ecolabel | European Union | Recognizes products with reduced environmental impact throughout their life cycle. | Limited use of hazardous chemicals, efficient resource use, and waste reduction. | Enhances brand reputation and enables product sales within the European market. |

| EcoLogo (UL Environment) | Underwriters Laboratories | Certifies low environmental impact across manufacturing and product use stages. | Assessment of energy use, air and water emissions, and biodegradability. | Validates sustainable production and supports green marketing efforts. |

| ISO 14001 | International Organization for Standardization | Establishes an environmental management system (EMS) for manufacturers. | Continuous environmental performance improvement, pollution prevention, and legal compliance. | Ensures sustainable operations and boosts compliance with global regulations. |

| Carbon Neutral Certification | Various accredited organizations (e.g., Climate Active, Carbon Trust) | Verifies that carbon emissions from production are measured and offset. | Accurate carbon accounting, verified offset projects, and emission reduction strategies. | Strengthens environmental responsibility and aligns with carbon reduction commitments. |

| Green Seal | Green Seal Organization (U.S.) | Evaluates environmental performance, health, and product safety. | Limits on toxins, sustainable packaging, and lifecycle-based environmental criteria. | Offers credibility in eco-labeling and supports market differentiation. |

| Nordic Swan Ecolabel | Nordic Ecolabelling Board | Certifies products meeting strict environmental and health standards in Nordic countries. | Restricted chemicals, sustainable raw materials, and low emissions during production. | Facilitates market entry in Northern Europe and highlights premium environmental performance. |

| Compostable / Biodegradable Certification | Various (e.g., TÜV Austria, BPI) | Confirms that products or packaging decompose naturally without harming the environment. | Proven biodegradability and compostability under controlled conditions. | Supports eco-friendly disposal and promotes circular economy practices. |

| REACH Compliance | European Chemicals Agency (ECHA) | Regulates the safe use of chemicals in production within the EU. | Registration and restriction of hazardous substances; ensuring safe chemical management. | Ensures consumer safety and compliance with European chemical standards. |

Final Thoughts

The quality standards for bamboo tissue paper include the environmental, mechanical, and hygiene qualities to guarantee the consumer receives a product that is safe, soft, and sustainable, and to safeguard the consumer’s health. The achievement of international quality and environmental standards, including ISO, FSC, and Ecolabel, is evidence that the manufacturer cares about the excellence of their product and about promoting the health of the environment. As consumer awareness of environmental and social responsibility increases, these standards will be a major determinant of bamboo tissue brands’ global credibility and success.