How to Ensure the Safety in Toilet Paper Manufacturing

The toilet paper production seems simple, however, ensuring safety during manufacturing is essential to avoid the risk of contamination, workplace hazards and product defects. From the initial handling of raw materials until the final packaging, toilet paper manufacturers must follow strict safety standards to protect the workers, the consumers and the environment. This article focus on the key safety measures to be taken in toilet paper manufacturing as well as the regulatory standards and the emerging new safety trends in the paper manufacturing industry.

The Key Steps in Toilet Paper Manufacturing

| Step | Description |

| 1. Pulp Preparation | The wood is recycled, virgin or reclaimed paper or bamboo is transformed into pulp with water, chemical or mechanical processes. |

| 2. Cleaning and Deinking | Recycling materials are cleaned in order to remove inks, adhesives and contaminates. |

| 3. Bleaching (if needed) | Pulp is whitened by using safe bleaching agents, such as chlorine or oxygen-free compounds. |

| 4. Mixing and Additives | The addition of fragrances, softeners or lotions are used to increase the quality and texture of the product. |

| 5. Sheet Formation | Pulp is sprayed on the moving mesh screen. the water drains and the fibers begin to form bonds. |

| 6. Pressing and Drying | Sheets are dried and pressed with heated rollers that remove water and smooth the paper. |

| 7. Creping | A blade made of metal scrapes the dried sheet off the dryer, resulting in an elastic and soft surface. |

| 8. Reeling into Jumbo Rolls | Continuous sheets are then wound into huge jumbo rolls to allow to be further processed. |

| 9. Converting | Jumbo rolls are not wound or rolled, embossed, perforated and then cut in smaller pieces. |

| 10. Packaging | Toilet paper rolls that have been finished are wrapped automatically in a label, then packaged to be distributed. |

Key Safety Risks in Toilet Paper Manufacturing

| Category | Safety Risk | Description |

| Raw Material Contamination | The chemical or biological residues are a source of contamination. | Recycled pulp or paper that has not been properly treated could create harmful microbes or chemicals. |

| Airborne Contaminants | Fiber and dust particles | Fine particles from the pulp process can trigger respiratory issues or even contaminate the product. |

| Machinery Hazards | Sharp blades, moving parts rollers | The high-speed machinery can result in injuries, abrasions or even entanglement if there are no safeguards. |

| Worker Exposure | Cleaning chemicals or hot surfaces | Cleaning and maintenance processes can expose workers to burns or irritation. |

| Microbial Growth | Humid production environments | Conditions that are humid in storage areas or production areas could encourage bacterial or mold growth. |

| Improper Packaging | Cross-contamination during final handling | Lack of proper packaging controls could cause a compromise in hygiene prior to distribution. |

| Noise and Vibration | Exposed for a long time to loud equipment | People may experience fatigue or loss of hearing if they do not wear appropriate equipment for protection. |

| Electrical Risks | Equipment or wiring that is not working properly | It can cause electrical shocks or fire hazards in manufacturing installations. |

| Chemical Handling | The use of bleaching agents as well as adhesives or fragrances | Incorrect handling could cause skin irritations or even inhalation dangers for workers. |

| Waste Disposal Issues | Inadequate treatment for wastewater or paper residues | Pollution from the environment can cause legal violations and unsafe work working conditions. |

Essential Safety Measures in Toilet Paper Manufacturing

1. Safe Raw Material Sourcing

Security begins by selecting the appropriate materials. Finding reliable suppliers who have established quality records and safety control is crucial to avoid contamination from the beginning.

| Raw Material Type | Safety Considerations | Advantages | Precautions Required |

| Virgin Wood Pulp | Deinking and disinfection is required to eliminate adhesives, inks and contaminants | Strong and soft with high levels of softness. | Be sure to avoid bleaching agents that are harmful or pesticide residues |

| Recycled Paper | Naturally antibacterial, rapidly growing, and a sustainable source | Eco-friendly, economical | Complete sanitization and testing for chemical or microbial impurities |

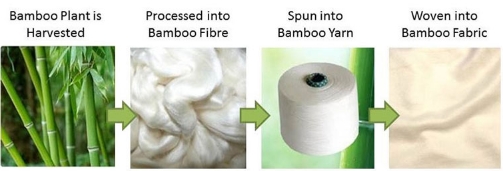

| Bamboo Pulp | Naturally antibacterial, rapid-growing and a sustainable source | Hypoallergenic, eco-friendly, tough but soft | The product must not contain harsh chemicals and must be sourced from a clean source |

| Blended Materials | Mixture of recycled and virgin or bamboo pulp for efficiency and sustainability | Environmental impact and balance of quality | Every component has to be independently checked for safety conformity |

| Additives (e.g. lotion and fragrance) | It must be dermatologically tested and approved for contact with skin | A better user experience and comfort | Ensure no allergens, irritant |

2. Hygiene Standards in the Production Environment

A safe and clean environment is crucial to prevent contamination during the manufacturing process. Facilities should be outfitted with the latest air filtration technology to minimize dust and microbes that are borne by air. The floors, walls and other surfaces should be cleaned regularly and disinfected. Additionally, humidity levels should be controlled to limit the growth of microbial. Employees must adhere to strict hygiene standards, such as wearing clean uniforms and gloves, face masks and hairnets, particularly in places where paper is transformed and packed.

3. Machine Safety and Operator Protection

Advanced toilet paper production line relies on high-speed equipment like embossers, jumbo roll unswinders perforators, rewinders and embossers. These machines can pose mechanical hazards if they are not adequately protected. To ensure safety for the operator machines should be equipped with safety covers and emergency stop systems as well as safety locks. Regular inspection and maintenance of all equipment minimizes the risk of injuries. Employees must be properly trained in operating procedures as well as emergency response procedures to operate machines safely and with confidence.

4. Product Testing and Quality Assurance

The final product should be safe for contact with skin and reliable when used. The most important safety and quality tests include:

- Testing for microbiological contaminants to ensure that there are no harmful mold and bacteria.

- Analyzing chemical residues, particularly on bleached or scented paper to determine irritations.

- Testing for strength and softness to verify usability, without discomfort or disintegration.

- Biodegradability and flushability tests to avoid plumbing issues and ensure environmental safety.

Manufacturers should keep meticulous documents for each batch in order to identify and resolve any quality problems.

5. Regulatory Compliance and Certification

The production of toilet paper is governed by various safety regulations based on the location. This includes:

- FDA Standards for Hygiene Products (U.S.)

- EU REACH rules regarding chemical safety (Europe)

- ISO certifications, for example ISO 9001 for quality management and ISO 14001 for environmental management

Compliance assures that products comply with recognized standards for safety and protects companies from reputational or legal damage.

6. Environmental Safety and Waste Management

Environmental safety plays an essential part in the overall security strategy. Effective waste management systems need to be implemented to handle waste and dispose of solid waste safely. Making use of eco-friendly raw materials such as bamboo material, recycled paper, etc, and cutting down on energy use and water usage and encouraging recyclable or biodegradable packaging are all part of an environmentally sustainable and safe manufacturing process. These initiatives not only safeguard the environment, but as well the health of workers and the communities around them.

Emerging Safety Innovations in Toilet Paper Manufacturing

Toilet paper production is advancing beyond the traditional methods of production and modern facilities embrace innovative technologies and practices which improve hygiene, safety as well as environmental sustainability.

1. Advanced Antimicrobial Treatments

The latest antimicrobial additives and coatings are being developed, and then integrated into the production lines for toilet paper. These treatments to reduce the chance of contamination from microbial sources in transportation and storage without compromising skin safety. Natural antimicrobial substances such as silver ions and plant-based extracts are becoming more popular over synthetic chemicals because of their biocompatibility and environmental security.

2. Closed-Loop Raw Material Handling Systems

To limit the risk of contamination and increase traceability, companies are using closed-loop technology to handle raw materials. These systems facilitate the movement of fibers and pulp in silos and pipelines sealed and silos, which minimizes the exposure of workers to airborne and dust particles as well as securing materials from pollution from the environment.

3. Real-Time Monitoring and Smart Sensors

Smart manufacturing is changing production of toilet paper by integrating real-time monitoring techniques. Sensors that are connected to the Internet of Things monitor the quality of air, temperature, humidity, and performance of machines in the floor of the factory. These sensors alert operators to potentially dangerous conditions such as an increase in dust levels or unusual equipment vibration, before they escalate into security incidents.

4. Chemical-Free or Low-Impact Bleaching Technologies

New bleaching techniques like oxygen-based or enzyme-assisted processes offer better alternatives to chlorine bleaching. These techniques reduce the emission of harmful byproducts, and result in an environment that is cleaner and safer without compromising softness or whiteness. They also increase safety for workers by limiting contact with corrosive materials.

5. Automated Quality Inspection Systems

The use of AI cameras and Vision Systems is being utilized to examine toilet paper in real time for contamination, defects and irregularities. They reduce the need for manual inspections, and improve the consistency of quality. Automated reject systems to prevent products that are defective from reaching customers, assuring the safety of consumers and ensuring compliance.

6. Touchless Packaging and Handling Systems

To limit contact with humans and reduce risk of contamination, a number of manufacturers are introducing touchless and robotic handling systems that can be used for converting packaging, stacking and packing toilet rolls of paper. These systems ensure hygiene standards and improve worker security through reducing repetitive manual labor and exposure to machines.

7. Eco-Safe Bamboo Processing Technologies

Bamboo toilet paper is increasing in popularity because of its environmental sustainability and natural antibacterial characteristics. Innovative bamboo fiber processing, such as low-temperature drying that is chemical-free, making it more safe to make in a way that produces less pollution and less use of chemical. The processes also preserve the fiber’s hypoallergenic properties.

8. Predictive Maintenance Using AI and Machine Learning

Predictive tools for maintenance use AI algorithms to analyse machine data and predict failures prior to they occur. This breakthrough not only stops breakdowns in equipment but also lowers risks to safety for maintenance personnel. It ensures uninterrupted operation in a more secure, efficient work environment.

Final Thoughts

The safety of toilet paper manufacturing is a comprehensive commitment to every aspect of production starting with raw materials and manufacturing practices to the final product testing and environmental responsibility. Since it is a product for daily use, toilet paper should be able to meet the high standards of hygiene, gentleness and quality. By following strict safety guidelines in compliance with regulations and an attitude of constant improvement, toilet paper manufacturers can make sure the products are secure for both consumers and workers. As demand for environmentally friendly and hygiene continues to grow and the toilet paper manufacturing industry is required to keep continue innovating to ensure safety throughout the production stage.