Hand Paper Towel Manufacturing Process and Material Guide for Commercial Buyers

The role of hand paper towels in hygiene management across commercial washrooms, food service facilities, healthcare environments, and industrial workplaces is critical. Even though they seem to be very basic, the operation of a hand paper towel is dependent on multiple technical factors, such as the hand paper towel types, the material composition, the ply structure, the GSM, and the manufacturing process.

By knowing the effects of various hand paper towel types and materials on absorbency, strength, softness, and sustainability, people can even out the purchasing variables, including both hygiene performance and long-term operating costs. This guide is the provider of the complete introduction to hand paper towel types, materials, and how hand paper towels are made, which backs up smart procurement practices.

Hand Paper Towel Types for Commercial and Household Use

Folded Hand Paper Towel Types

Folded hand paper towels are among the most widely used disposable hand paper towel options in commercial washrooms.

Common folded formats include:

- C-fold hand paper towels

- Z-fold (V-fold) hand paper towels

- M-fold (multi-fold) hand paper towels

These styles of hand paper towels come folded to facilitate controlled dispensing, which in turn helps to reduce cross-contamination and overall paper waste. Their main use is found in offices, hospitals, schools, and places where cleanliness is a must.

Folded hand paper towels go well with wall-mounted dispensers and are suitable even for the washrooms with moderate to high usage.

Roll Hand Paper Towels

Roll hand paper towels are designed for high-capacity environments and continuous usage.

Popular roll formats include:

- Center-pull hand paper towel rolls

- Auto-cut or sensor-operated roll hand towels

Compared with folded hand paper towels, roll hand paper towels offer:

- Longer refill intervals

- Lower maintenance frequency

- Better suitability for high-traffic commercial washrooms

In the folded hand paper towel vs roll hand towel comparison, rolls often provide cost efficiency at scale, while folded options offer greater hygiene control.

Single Ply vs Multi Ply Hand Paper Towels

One of the most important structural differences in hand paper towels is single ply vs multi ply construction.

Single-Ply Hand Paper Towels

- Made from one layer of tissue

- Lower material consumption

- Cost-effective for large-scale usage

- Slightly lower absorbency per sheet

Multi-Ply Hand Paper Towels (2-ply / 3-ply)

- Higher absorbency and wet strength

- Improved softness and hand feel

- Fewer sheets needed per use

A large number of purchasers in the business sector tend to buy 2-ply hand paper towels as they give an equilibrium of absorption power, strength, and low cost.

Hand Paper Towel Materials: Virgin Wood and Bamboo Pulp Options

Material selection is a key factor that determines absorbency, softness, durability, and sustainability. Modern hand paper towels are primarily produced using three refined material structures.

Virgin Wood Pulp Hand Paper Towels

Hand paper towels made from virgin wood pulp are known for their consistent fiber quality and high absorbency.

Key advantages include:

- Superior softness

- High water absorption capacity

- Clean, uniform appearance

People typically use high-quality paper towels made from virgin wood pulp in luxury commercial restrooms, hotels, and healthcare buildings that prioritize comfort and performance.

Virgin Wood and Bamboo Pulp Mixed Hand Paper Towels

Virgin wood and bamboo pulp mixed hand paper towels combine the performance stability of wood fibers with the sustainability advantages of bamboo.

Main benefits include:

- Balanced absorbency and strength

- Improved bulk at optimized GSM levels

- Reduced reliance on pure wood pulp

The use of these mixed material constructions is continuously growing in the case of commercial toilets, where they have come to represent an economical, green, and performance-wise balanced choice and thus have become a good choice for large-scale purchases.

Virgin Bamboo Pulp Hand Paper Towels

Hand paper towels made from virgin bamboo pulp represent a fast-growing category in eco-oriented hygiene products.

Advantages of virgin bamboo pulp include:

- Rapidly renewable raw material source

- Naturally strong and flexible fibers

- Good absorbency even at lower GSM

Virgin bamboo pulp hand paper towels have been the major choice for most of the brands and facilities that love and support nature, reduce carbon, and abide by green building standards.

Hand Paper Towel Material Comparison Table

To help buyers quickly compare different material options, the following table summarizes their key performance characteristics:

| Procurement Scenario / Decision Factors | Virgin Wood Pulp Hand Paper Towel | Virgin Wood & Bamboo Pulp Mixed Hand Paper Towel | Virgin Bamboo Pulp Hand Paper Towel |

| Raw Material Composition | 100% Virgin wood pulp | Virgin wood pulp + virgin bamboo pulp | 100% Virgin bamboo pulp |

| Softness | ★★★★☆ | ★★★★☆ | ★★★☆☆ |

| Absorbency | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Wet Strength | ★★★★☆ | ★★★★☆ | ★★★★☆ |

| Recommended GSM Range | 20–24 GSM (single-ply) | 20–24 GSM (single-ply) | 18–22 GSM (single-ply) |

| Cost Level | Medium | Medium–High | High |

| Quality Stability | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Sustainability Performance | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Typical Ply Structure | 1-ply / 2-ply | 1-ply / 2-ply | 1-ply / 2-ply |

| Compatible Towel Type | Folded / Roll | Folded / Roll | Folded / Roll |

| Typical Application Scenarios | Offices, hotels, hospitals, restaurants | Commercial washrooms, eco-friendly offices | High-end commercial spaces, sustainability-focused projects |

| Recommended Procurement Strategy | Stable long-term procurement | Performance + sustainability balanced procurement | Brand upgrade / ESG-oriented procurement |

How Hand Paper Towels Are Made: Step-by-step for Manufacturing Process

Understanding how hand paper towels are made helps buyers evaluate product quality and supplier capability.

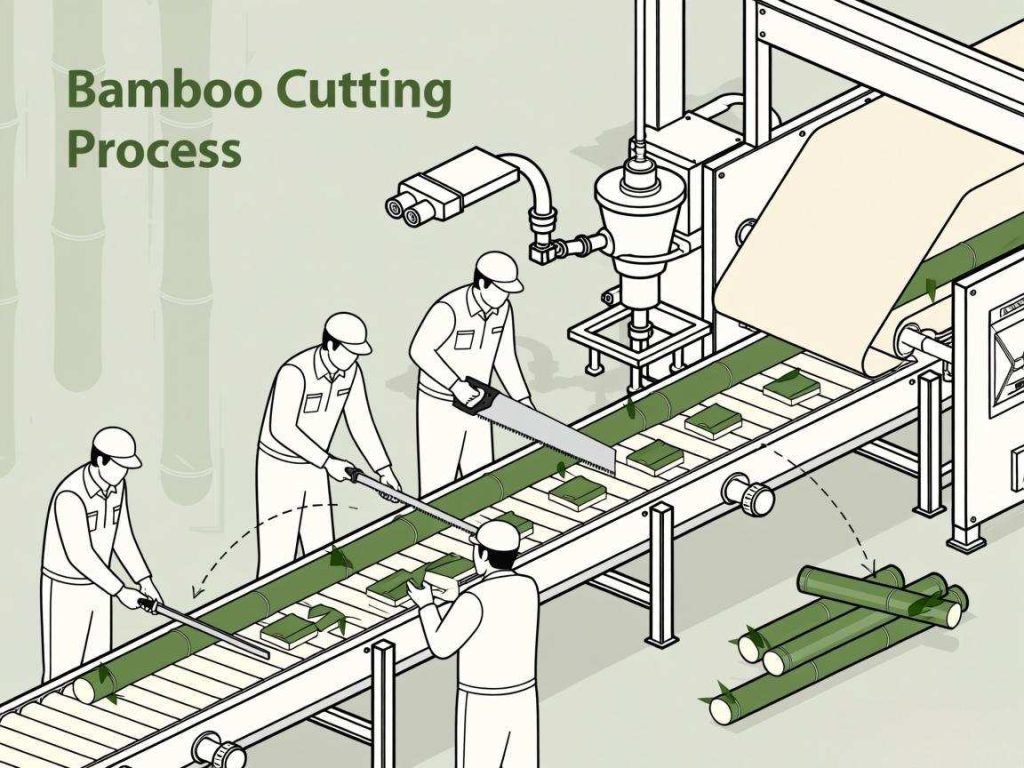

Pulp Preparation and Fiber Refining

The initial stage consists of choosing the right raw material: virgin wood pulp, virgin wood and bamboo pulp mixture, or virgin bamboo pulp.

Key processes include:

- Pulping: Fibers are either physically or chemically removed from the pulpy materials. Virgin pulp is usually purified to eliminate any dirt, while mixed or bamboo pulp could go through an additional mixing process to ensure that the fiber is evenly distributed further.

- Fiber Refining: In this phase, the fiber length, fibrillation, and fiber bonding capacity are adjusted, which are the three main parameters of the paper, which are softness, wet strength, and absorbency.

- Additives and Wet Strength Agents: Depending on the wanted product performance, a small amount of natural softeners or wet strength agents could be added to increase the durability and hand feel of the paper.

Good pulp preparation is essential to make sure that the paper produced is uniform, regular, and meets the defined GSM and bulk specifications.

Sheet Forming on Tissue Paper Machines

After being refined, the pulp and water mix is then transferred to high-speed tissue paper machines, where the water is drained away, and the fibers start to form continuous patterns.

Sheet forming is heavily influenced by the following factors:

- Consistency Control: Keeping the right pulp-to-water ratio guarantees equal thickness and density all throughout.

- Fiber Orientation: The fibers are minimally oriented across the machine direction to allow the right balance of tensile strength and softness.

- Initial Pressing: Pressing action is gently applied to get rid of extra water while at the same time maintaining the sheet’s bulkiness for absorbency.

At this stage, the absorbency, strength, and texture in the end product of the hand towel are already being provided.

Drying, Creping, and Softening

The wet sheet undergoes creping and is then dried, a process that determines the tactile attributes and bulk of the hand paper towels.

- Drying Cylinders: Hot drying cylinders efficiently take out the rest of the remaining moisture, and at the same time keep the structural integrity.

- Creping: By scraping with a flexible steel blade the sheet off the dryer cylinder, microscopic folds are created. This step boosts the paper’s softness, stretch, and liquid absorption without the need for increasing the GSM.

- Calendering (Optional): For top-notch products, gentle calendering gives the paper a smooth texture while preserving a fluffy structure.

The proper drying and creping operations must be conducted to provide the most user-friendly hand paper towels that are strong when wet and absorb water well.

Embossing, Cutting, and Converting

The last step changes the paper into its selling form.

- Embossing: The tissue is stamped with patterns to make ply bonding, touch, and water support.

- Ply Layering: Various amounts of ply (usually one, two, or three) are put together, bonded, and sometimes perforated to make it easier to dispense.

- Cutting and Folding/Rolling: The sheets are then cut to the standard form and folded (C-fold, Z-fold, M-fold) or rolled (center-pull, auto-cut) to match the request of the market.

- Quality Inspection and Packaging: Batch after batch is strictly inspected visually, in dimensions, and in absorbency with respect to the packaging conditions so that the hygiene and business regulations are not violated.

GSM and Absorbency: Key Performance Indicators

GSM (grams per square meter) is a fundamental specification in hand paper towel selection.

Typical GSM ranges:

- Single-ply hand paper towels: 18–25 GSM

- Multi-ply hand paper towels: Total 32–45 GSM

Higher GSM typically results in more sustainability and strength, but with advanced manufacturing, manufacturers are able to obtain high absorbency even with the optimized GSM through fiber selection and embossing design.

Having the information about paper towel GSM and absorbency brings the buyers to a position where they are neither overspecifying nor under-specifying, and therefore, they can be in control of the cost.

Conclusion: Aligning Hand Paper Towel Types, Materials, and Manufacturing Quality

Hand paper towels are a critical hygiene product where performance, sustainability, and cost intersect. A purchaser can confidently make data-driven decisions by understanding hand paper towel types, material options, ply structure, GSM standards, and the manufacturing process.

Through partnering with experienced tissue paper manufacturers as well as selecting products that meet your operation needs, consistent quality, reduced waste, and improved user satisfaction are guaranteed.